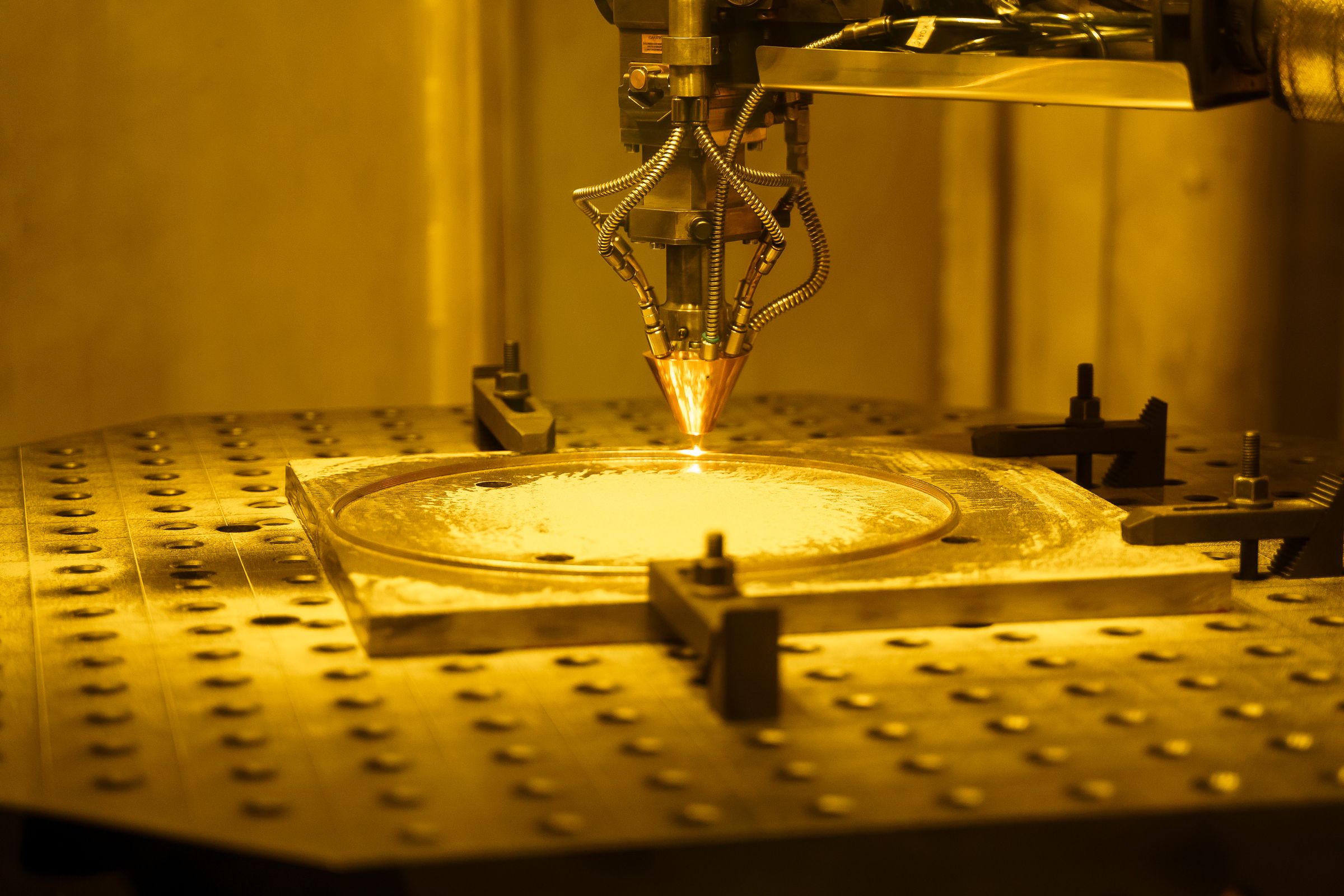

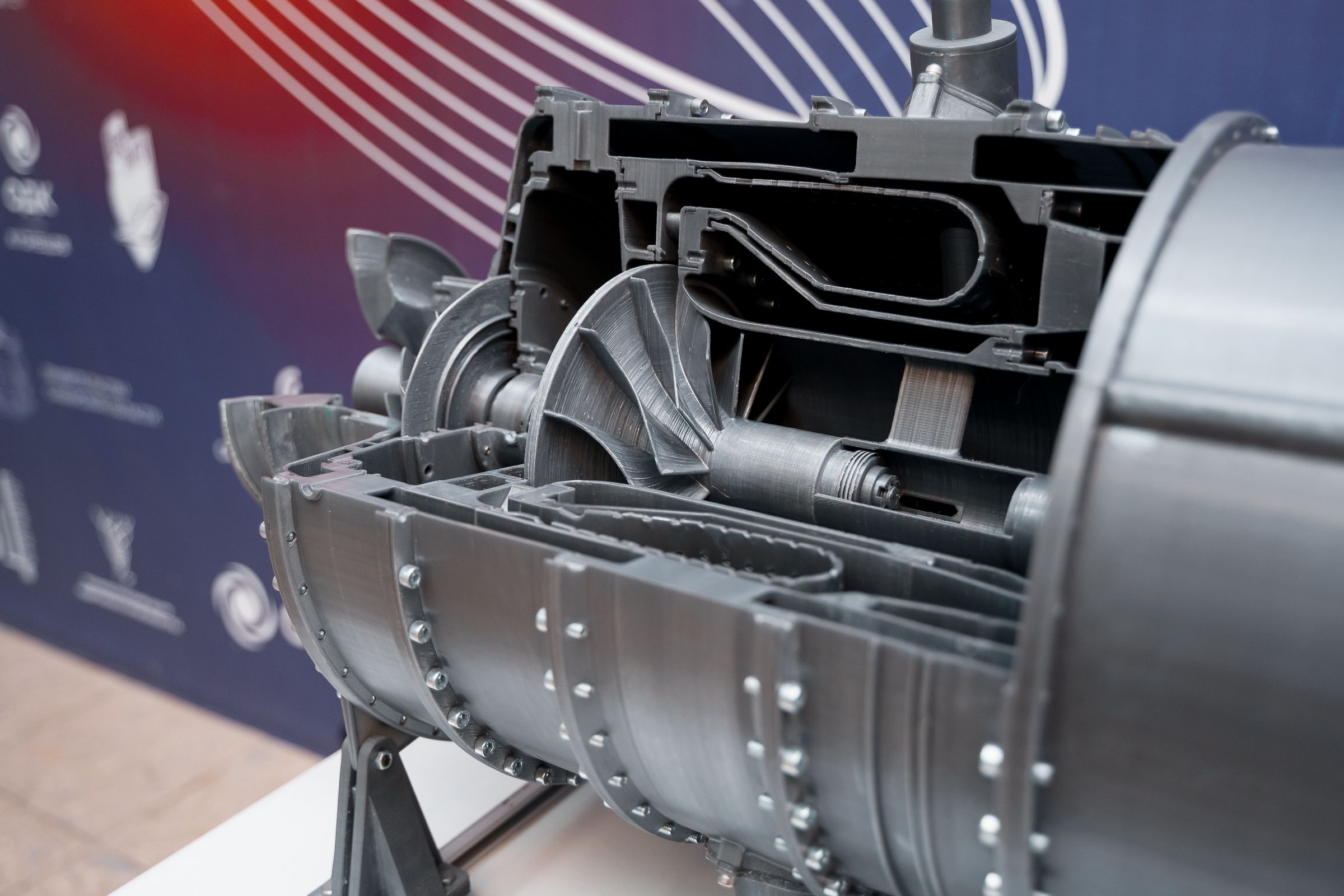

It includes processes of selective laser melting (SLM), direct laser deposition (DLD), as well as thermal and mechanical processing. The technology was tested on five types of low-emission combustion chamber (LECC) parts: these are the burner device, the outer and inner casings of the combustion chamber, as well as the outer and inner rings of the pre-swirl system. The LECC is characterized by increased eco-friendliness, and is designed for power facilities.

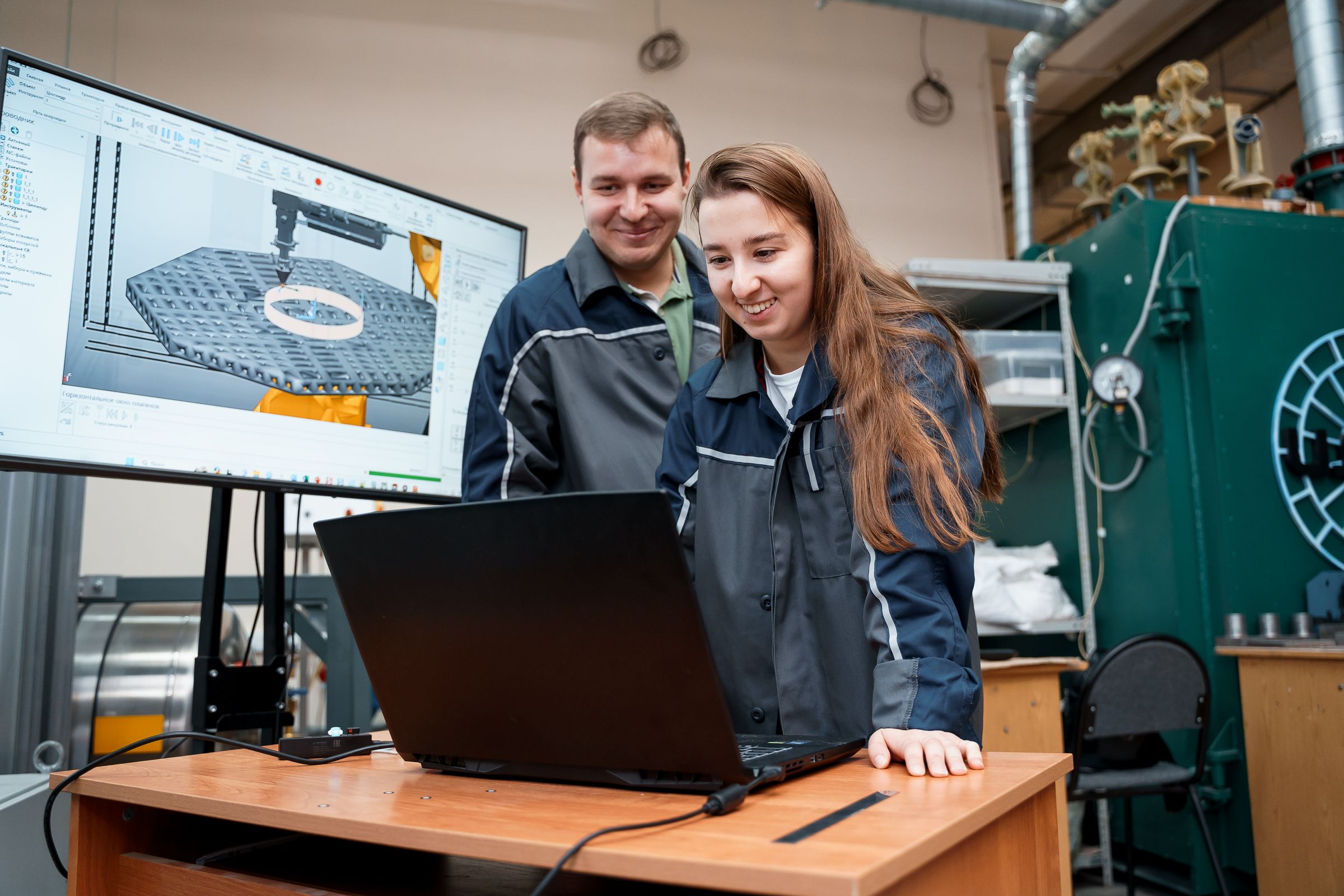

“In addition to the direct fine-tuning of technological processes, we have created the intelligent system of design and technological preparation of production based on LOTSMAN:PLM. Using digital technologies, it links together all stages of product creation – from the designer’s idea to its embodiment in metal. In other words, from the stage of its engineering study to the stage of manufacturing the parts on industrial additive machine right in the workshop of the enterprise. The methodology of digital organizational design and technological preparation of additive production has also been developed. All these developments have now been handed over to the industrial partner and implemented”, told us Vitaly Smelov, Director of the Institute of Engine and Power Plant Engineering.

The project started in 2021, to be divided into five stages. It took three years to implement it. Financing was allocated by the Resolution of the Government of Russia No. 218.

The industrial partner of Samara University was “ODK – Kuznetsov” PJSC. Due to the project, this enterprise of the United Engine Corporation (UEC, part of Rostech) has now launched the comprehensive high-tech production of parts and assemblies of the hot part of industrial GTE, based on additive technologies, as well as has been modernized its DLD machine.

Pavel Chupin, General Designer of “UEC – Kuznetsov” PJSC, considers that the most significant development of this project is “The Methodology of Digital Organizational Design and Technological Preparation of Additive Production”. By applying it, the plant designers and technologists can develop the 3D printing process for any product. In particular, to set required geometric shapes, select optimal fusion modes, and evaluate specifications of materials in the finished part.

As for the intelligent system of integrated design and technological preparation of production (KTPP) of industrial gas-turbine engine parts, it is also implemented at the enterprise and integrated into the single digital circuit based on its PDM system.

“Applying additive technologies combined with the intelligent KTPP system ensures reduction in the time required for the pre-production preparation and manufacturing parts of industrial GTE with enhanced properties”, noted Pavel Chupin.

As explained by Victoria Kokareva, Associate Professor at the Department of Engine Production Technology, introducing 3D printing methods and intelligent systems makes the production process more efficient, reduces time spent, as well as material and financial costs.

“When manufacturing products using conventional technologies – stamping, cutting, welding – as a rule, specialized equipment is required, often expensive one, and its design and manufacturing takes a lot of time. In conditions of large-scale production, this is not so crucial. But when developing new products, at the stage of pilot production, time and cost factors come to the fore. It is here, in pilot production, that advantages of additive technologies are fully observed”, explained Victoria Kokareva.

The integrated high-tech production created at “UEC – Kuznetsov” PJSC ensures high material utilization rate of over 70%, and the yield of usable metal products (given the reuse of powder) is at least 95%.

Volumetric printing technologies can also make it possible to increase efficiency of classical technological processes – for example, casting on burnable and smelted models, if these models are printed from plastic and wax on 3D printers. This is also very important for engine-building enterprises.

In general, introduction of Samara University’s developments promises engine builders considerable effects. In turn, for the University, new opportunities have also opened up: in particular, due to new additive machines acquired with the project funds. They are similar to those that production sites of “UEC – Kuznetsov” PJSC are equipped with, the difference is only in size: the University’s machines are slightly smaller than the industrial ones.

“By the beginning of the project, we had already been able to grow medium-sized products using SLM technology. Machines with more powerful lasers, working with larger-fraction powders, led us to printing products over a meter in size. In partnership with the ILIST company, the machine of which is used at the University, we have managed to significantly master our competencies in the field of PLV technologies. In particular, the tests showed that mechanical properties of our products made of EP648 heat-resistant alloy powder correspond to the properties of samples obtained from rolled products of the same brand”, shared their achievements Andrey Balyakin, an engineer at the Engineering Centre of Samara University.

The size and capacity of the machines matter: now the University is able to help production workers not only with research, but also by participating in fulfilling production orders.

“The additive machines M-350 and ILIST, which appeared in the EPPE laboratories due to the project, make it possible for us not only to explore and work out technological processes for an industrial partner, but also to integrate into its cooperative chain. If necessary, we will be able to produce small batches of parts at the University, participating in modernization of mass-produced engines and development of new ones”, added Vitaly Smelov.

As noted by Victoria Kokareva, from the very beginning of the project, new additive machines were used in the educational process.

“The EPPE students and postgraduate students were engaged in programming the Fanuc robot, selecting and analyzing technological modes of direct laser deposition. And besides, employees of “UEC – Kuznetsov” PJSC took our advanced training courses”, explained Victoria Kokareva.

For reference:

Within the framework of the Project “Organization of high-tech production of industrial GTE with the intelligent system of design and technological preparation to improve functional specifications”

- The complex technology for additive manufacturing of parts and components of the hot part of industrial gas-turbine engines has been developed.

- The methodology of digital organizational design and technological preparation of additive manufacturing has been created.

- The intelligent system of integrated design and technological preparation for production of parts of industrial GTE has been created.

- The ILIST machine for technological laser deposition has been modernized in the interests of “UEC – Kuznetsov” PJSC, the industrial partner of the project.

- The comprehensive high-tech production of parts and components of the hot part of industrial GTE, based on additive technologies has been created.

RU

RU  EN

EN  CN

CN  ES

ES