Samara University began serial production of vibroinsulators made of metal rubber in the frame of the big order from Sinara Group holding. The unique material exceeds the analogues known in Russia and abroad and will be used in the latest domestic high-speed diesel engines of locomotives.

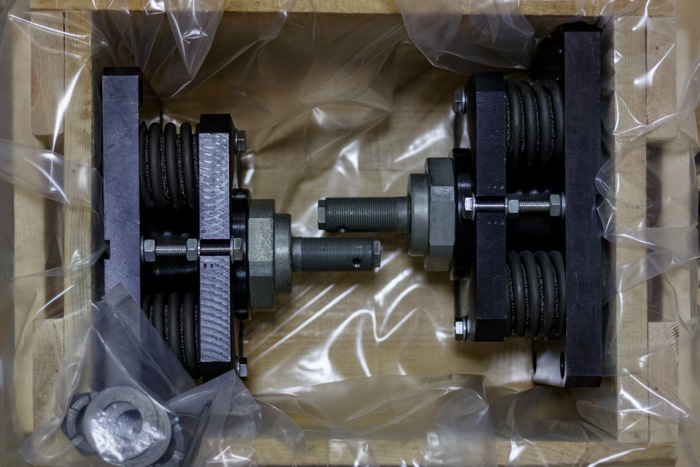

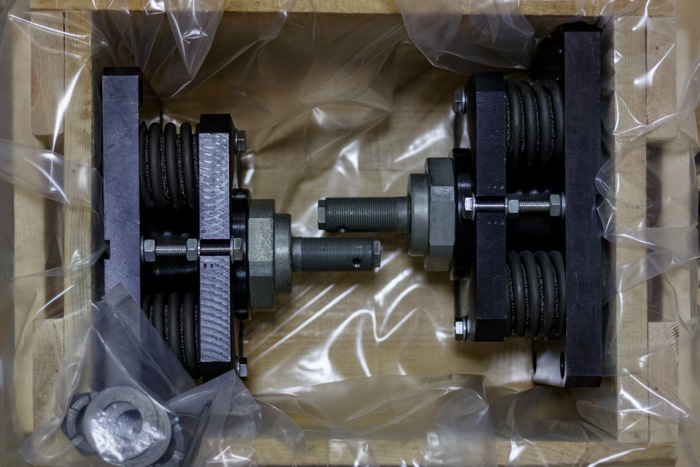

The development of serial production of vibroinsulators made of metal rubber (MR) began in June 2017 on order of machine building Sinara Group holding – JSC “Sinara-Transport Machines”.

Let us remind that in July 2016 scholars of Samara National Research University were offered by the holding to develop a system of vibroinsulation for the latest domestic high-speed diesel engines for locomotives as dampers on the basis of MR in their safety and resource substantially exceed the known analogues in Russia and abroad. As a result of project work in the research laboratory “Vibration strength and safety of aircraft” (ONIL-1) of the university low-frequency highly damped vibroinsulators made of MR were created within the shortest possible time. The preproduction lot of the innovative production was successfully tested in Yekaterinburg on Urals diesel engine plant in April 2017, after that the university got a big order from the machine building holding for serial production.

Already in July 2017 the employees of ONIL-1 developed a serial production of the new product. Today big contracts the total sum of which reaches 18 million roubles are concluded with Sinara Group holding. On one of them in the end of July 2017 pilot batch of 80 vibroinsulators which will serve for 10 locomotives was delivered. One more contract presupposes the provision of the holding with 500 bases for locomotives till the end of 2017. With that the agreement presupposes prolongation, it means that cooperation of the university with the machine building holding will be continued.

“We remain leaders in the development of production technologies of MR. As a rule, production enterprises do not have an opportunity to do what we are doing – improvement, their main task is to increase the volume of production. We are pushed into innovations by life, - Danila Davydov, Deputy-head Constructor of ONIL-1 says. – Ministry of Science and Education of the RF has clearly defined the trend for development of research and educational institutions, we should earn on our own research findings”.

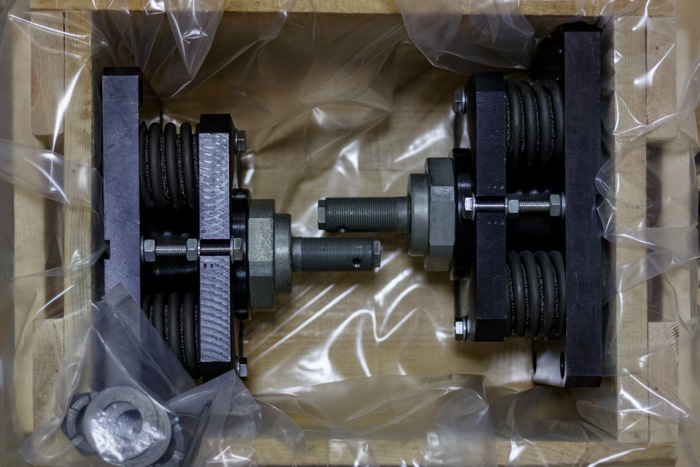

With that the responsibility of the employees of ONIL-1 at Samara University is not bound by the production of details made of MR, they also assemble vibroinsulators, provide their adjustment, multilevel control of characteristics, packing of products, issue of documents confirming the quality of the production with the execution of a guarantee.

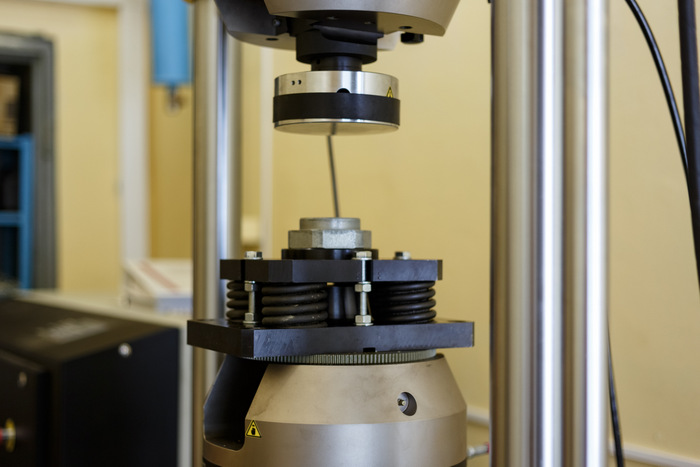

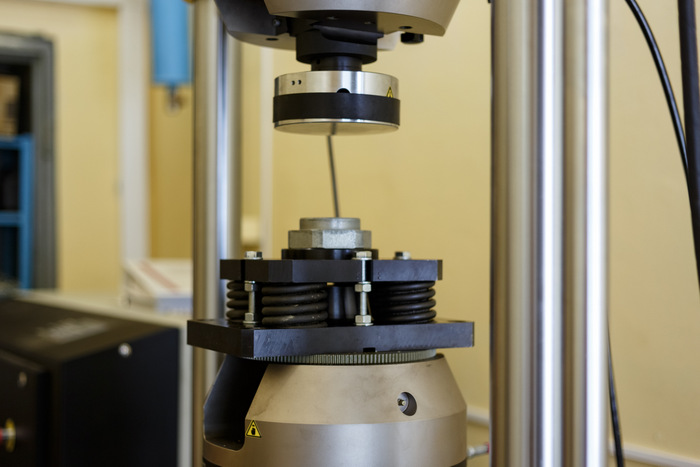

These vibroinsulators of MR have a guarantee of 24 months from the moment of launch of them in exploitation. There is also a more rigid parameter, i.e. expected life which means the time of faultless work of a mechanism. Sinara Group holding set a high standard of 70000 hours. According to the university scholars this is a serious requirement taking into consideration that in 25000 hours of work the locomotive is under major repair in the course of which many details are renovated or replaced for the new ones, but bases made of MR must continue normal operation.

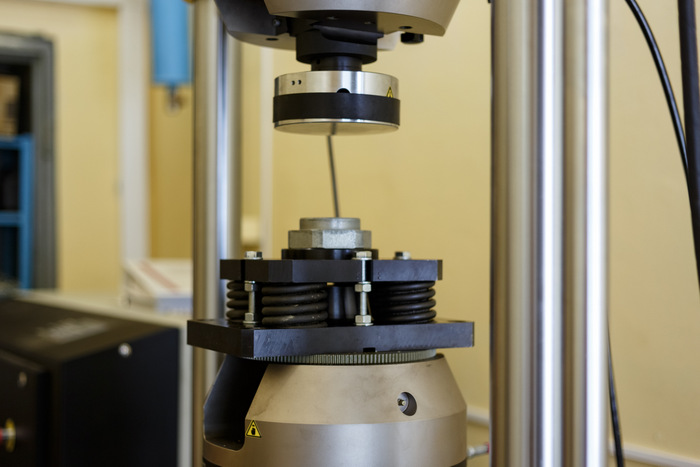

Now at the production and probation base of ONIL-1 research work on refining of resources is being made. Working influences on a vibroinsulators are imitated on special dynamic stands in laboratory conditions. For tests imitating the conditions of work in 70000 hours several years will be required, that is why at the university methods of short-time tests were developed, which allowed to reduce the time interval till several weeks preserving the precision of results. Real loads are replaced with more rigid and aggressive ones: higher regimes, amplitude, etc. These are the so called equivalent tests and their development requires a serious scientific base. To set equivalence is a complex scientific task, but in ONIL-1 a great scientific and technical base in this direction was formed and it allows solving it.

“Multilevel constructor element of this project should be mentioned, - Danila Davydov says. – The production of MR is very specific: all equipment that is used for its creation is constructed at Samara University, it is impossible to buy it anywhere. One cannot buy a machine for coiling, dissolution and laying a coil of metal rubber because this is unique equipment that is especially developed here in ONIL-1 for our aims and tasks”.

For provision of a big order in a serial production elements of automation are actively implemented, in the nearest future manual labour will be minimized. Even now a pilot plant of automated formation of preproduction lots is in action, but work on its improvement is being made in parallel. The second variant of the pilot plant is in its final version of production; its modernization is done with the consideration of the executed prototype testing. Moreover, coiling machines are being perfected; settings on formation of work pieces and pre-work pieces of new generations are being created. Modern electronic and mechanical solutions under the programmed logical controllers are being implemented.

In the near future there is a plan to make the production of body parts of vibroinsulators more technological; in particular for their production moulding will be implemented. Now the details are cut of a metal piece and surplus in the shape of metal shaving is wasted. Moulding is more economic, it allows getting details approaching the end form as much as possible.

Administrative structures of Samara University actively help to master the serial production of vibroinsulators on the basis of ONIL-1. For this project premises in different buildings of the university are given, additional working force is attracted. The laboratory is interested in the youth; today several students are participating in this project. The young shift (among them there are third year students) is given tasks that are interesting from scientific viewpoint and actual for production. The youths work under the guidance of experienced constructors and scholars of ONIL-1 over the latest variant of a setting with the numeric control for the production of items made of MR. Such machines do not exist, they are automation of the future.

For reference

Use of the systems of acoustic and vibration defence cannot only extend the durability in several times of a complex and expensive equipment, but to make its exploitation more convenient and comfortable for a person. That is why fundamental and applied research in the sphere to which use of elements on the basis if MR is applied are more and more claimed in many fields of machine building – as with production of transport, energy, automobile, metallurgy and petrochemical equipment as with knots of spacecraft.

Damping material of MR developed by the university scholars and produced in university laboratories has useful qualities of rubber and can resist aggressive environments; high and low temperatures and other stressed conditions. The secret lies in a special technology of weaving and pressing of spiral metal threads of different diameters.

The base of scientific and practical school of dynamics and vibroacoustics of machines was laid in Samara (Kuybyshev) more than half a century ago; today it is among the most authoritative ones in the world and is one of the “trademarks” of Samara University.

Photo: Natalia Orlova (Photo club “Illuminator”)